The Chemical Facility Safety spotlight has intensified following a recent report from the U.S. Chemical Safety Board (CSB), which calls on chemical plants nationwide to reinforce their emergency preparedness and awareness protocols.

This follows a July 2024 ammonia release at a food processing facility in Sterling, Virginia, operated by Cuisine Solutions Inc. The incident involved the release of nearly 170 pounds of anhydrous ammonia when an emergency pressure relief valve discharged unexpectedly, forming a dense white cloud of toxic gas.

During evacuation efforts, several workers accidentally exited near the ammonia cloud, leading to breathing difficulties and chemical exposure. In total, 33 employees were hospitalized, with four suffering serious injuries and one requiring intensive care.

5 Key Lessons for Stronger Chemical Facility Safety

To prevent similar accidents and improve Chemical Facility Safety, the CSB outlined the following essential recommendations:

- Strengthen Emergency Protocols

Ensure all employees understand evacuation routes, use of safety equipment, and the importance of immediate reporting during chemical incidents. - Record and Review Process Data

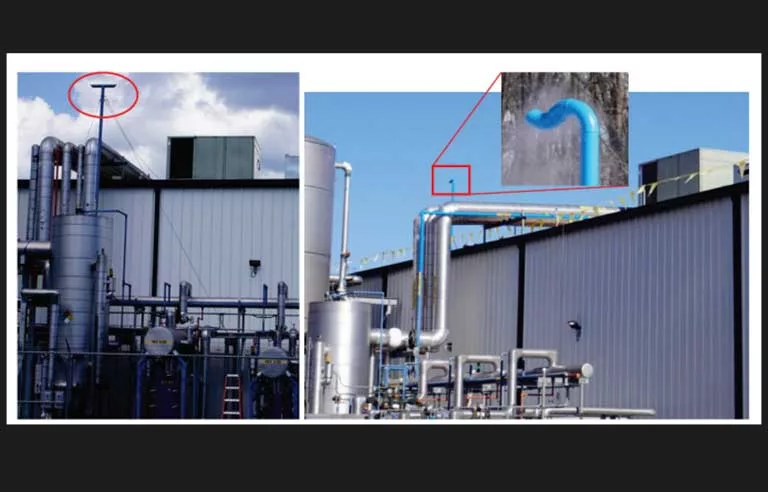

Regularly measure and document operational data to identify hazards early. Missing data can delay investigations and increase the risk of repeat incidents. - Upgrade Pressure Relief Systems

Inspect ammonia and gas relief components to ensure they safely discharge into the atmosphere without endangering workers. - Implement Clear Alarm Systems

Use unique, scenario-specific alarms and make sure every worker understands what each alarm signal means. - Train Backup Operators for Emergencies

Train multiple staff members on emergency shutdown procedures so that the response is not dependent on one person.

CSB Chair Steve Owens emphasized that toxic ammonia vapors pose serious risks and must be managed with precision and preparedness. He stated that companies must establish reliable safety systems and train their teams thoroughly to respond effectively during emergencies.

The Chemical Facility Safety report highlights that true workplace safety is built on prevention, education, and accountability. Facilities handling hazardous materials must not only invest in equipment but also in consistent employee training and safety culture.

About OSHAssociation.org

OSHAssociation.org is dedicated to promoting global occupational health and safety awareness. Through professional certifications, safety training, and international partnerships, the organization empowers industries to implement stronger Chemical Facility Safety standards and prevent workplace hazards. Visit www.oshassociation.org to learn how to strengthen your organization’s safety culture and protect lives at work.