The news that the Biffa Waste Services Ltd was fined nearly £2.5 million following the tragic death of a worker underscores how workplace transport and pedestrian segregation risks can no longer be treated lightly.

This case must serve as a wake-up call. On 10 August 2023, 57-year-old James Tabiri was walking across a weighbridge at Biffa’s Bradford waste-transfer station when a reversing skip wagon struck him from behind. He died from crush injuries caused by the rear wheels of the vehicle.

Following investigation by the Health and Safety Executive (HSE), Biffa pleaded guilty to breaching Regulation 5(1) of the Management of Health and Safety at Work Regulations 1999 and was fined £2.48 million plus costs.

In this article we unpack the full details of the incident, review the wider safety implications, and draw out seven key lessons that every business handling vehicle movements must learn. We also explore how organisations like OSHAssociation.org offer guidance and support for safer workplaces.

1. What exactly happened that Biffa fined nearly £2.5m?

Biffa fined nearly £2.5m after serious health and safety breaches that endangered workers and the public. The penalty highlights the growing enforcement of workplace safety laws and serves as a reminder that negligence in waste management and employee protection can lead to severe legal and financial consequences.

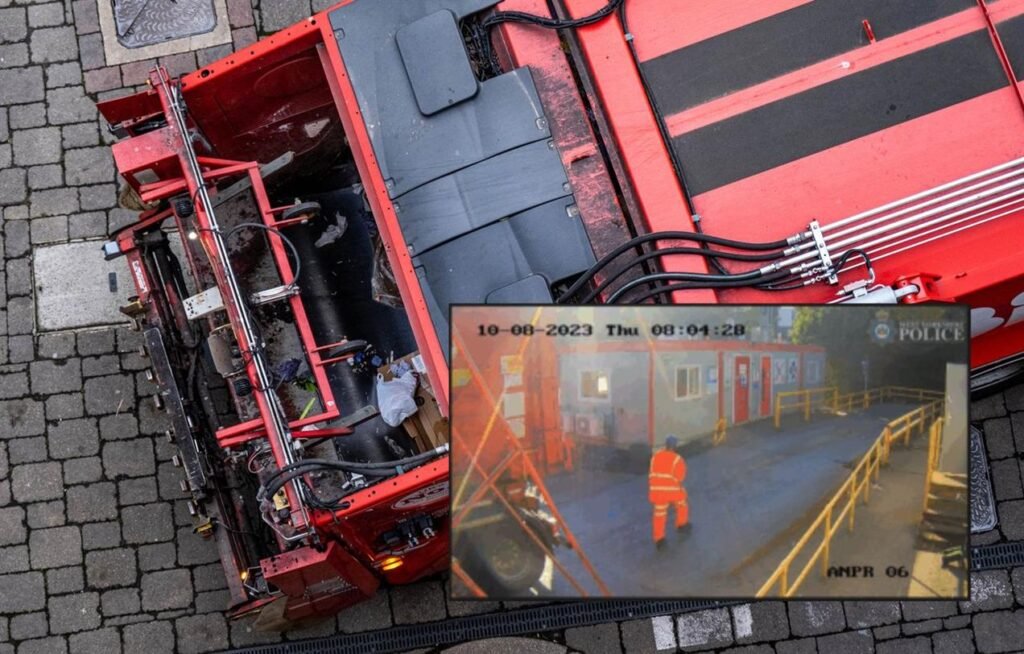

Biffa fined nearly £2.5m after a tragic incident that exposed serious safety failings at its Bradford site. Investigations found that the company’s system for keeping vehicles and pedestrians separate was routinely ignored. Although designated walkways and barriers existed, CCTV footage showed workers frequently climbing over them and taking shortcuts through vehicle zones.

On the day of the fatal accident, Mr. Tabiri walked toward the site office when a reversing skip wagon struck him from behind, causing fatal injuries as he fell beneath the vehicle’s rear wheels.

The HSE’s investigation concluded that although control measures existed (pedestrian routes, barriers), they were not effectively monitored or enforced. The UK+1

Inspector Elliot Archer commented: “This incident was easily avoidable… a lack of monitoring and supervision allowed poor working practices to develop.”

This sequence of events underscores how the presence of safety systems is not enough—active supervision, enforcement and behavioural safety are crucial.

2. Why does this matter?

The case where Biffa was fined nearly £2.5m highlights two critical lessons for workplace safety. Firstly, transport-related incidents remain one of the leading causes of fatalities and serious injuries at work, with the HSE reporting that almost a quarter of all workplace transport deaths occur during reversing operations.

Secondly, the substantial £2.48 million fine reflects how seriously courts and regulators treat failures of duty in high-risk environments. It serves as a strong reminder that simply installing segregated routes and barriers is not enough—companies must ensure these safety systems are actively followed, enforced, and regularly reviewed.

Thirdly, the reputational and operational impact on the business can be significant. The tragedy carries long-term cost beyond just the fine—disruption, loss of trust, inspections, remedial works and cultural damage.

Finally, for businesses outside the waste industry, it serves as a reminder that any operation involving vehicle-pedestrian interaction demands robust systems and behavioural oversight.

3. The duty of care and legal context

Biffa fined nearly £2.5m after admitting it breached Regulation 5(1) of the Management of Health and Safety at Work Regulations 1999, which requires employers to plan, organise, control, monitor, and review preventive and protective measures. Biffa also faced scrutiny under the general duty in the Health and Safety at Work etc. Act 1974 to ensure, so far as is reasonably practicable, the health, safety, and welfare of employees.

This case makes a crucial point: criminal liability can arise even when physical controls exist if they aren’t maintained, monitored, and enforced. In other words, non-compliance isn’t just “no barrier” or “no signage.” It’s also failing to ensure the safety system actually works in practice—precisely why Biffa was fined nearly £2.5m.

4. Key contributors to the incident

Biffa fined nearly £2.5m after the HSE found a series of contributory failings that turned a high-hazard site into a daily risk. Investigators concluded there was a fatal gap between the written safety system and real-world practice.

Key HSE findings (rewritten):

- Workers regularly ignored designated pedestrian routes and climbed over safety barriers.

- A casual attitude to health and safety prevailed, with staff treating a high-risk area like a playground.

- Supervision and monitoring of vehicle–pedestrian segregation were inadequate.

- Controls weren’t reviewed to confirm they still worked under actual site conditions.

- Management failed to learn from near-misses and recent CCTV evidence of unsafe route use.

Together, these points show that paper controls mean little without enforcement, cultural buy-in, and continuous review—core reasons why Biffa was fined nearly £2.5m.

5. Seven lessons every business must learn

5.1 Don’t assume controls work—verify them

Installing barriers and marked pedestrian routes is a start. But as this case shows, without active monitoring, workers may bypass them. Regular audits, observations and ideally CCTV review should be part of the process.

5.2 Behavioural safety matters

Even the best physical system will fail if workers treat the site informally. Leadership must not only set rules but model behaviours. A culture of supervision and accountability is essential.

5.3 Keep vehicle/pedestrian separation under constant review

Sites evolve, traffic patterns change, shortcuts emerge. What worked last year may not work now. Real-time observation of pedestrian movements, near-misses and rule violations must feed into review sessions.

5.4 Train, retrain and refresh

All workers—even those not directly handling vehicles—must understand the risks, the rules, the routes, and what happens when things go wrong. Regular refreshers help keep the hazard visible.

5.5 Use data from near-misses and observations

The fact CCTV footage showed unsafe practices prior to the incident indicates the business missed warning signs. Near-miss reporting, analysis and corrective action are essential.

5.6 Leadership involvement is key

Supervisors and management must remain visible in high-risk zones. They must walk the site, talk to workers, challenge unsafe behaviour, and ensure rules are being followed rather than just documented.

5.7 Don’t treat transport risk as routine

The case where Biffa was fined nearly £2.5m serves as a stark warning against complacency in managing workplace transport. In many organisations, vehicle movement is viewed as a routine or ‘standard operation’, but this mindset can be deadly.

Every reversing wagon, every weighbridge crossing, and every vehicle route must be recognised as a significant safety risk that demands strict control, supervision, and continuous awareness.

6. What Biffa did in response when Biffa fined nearly £2.5m

In its court hearing the company accepted the failures and committed to a full review of the site’s health & safety arrangements. The company’s Health & Safety Director stated: “We recognise in this case that the arrangements in place to ensure the safe separation of pedestrians and vehicles were not effective and we accept full responsibility.”

Remedial actions reported include redesigning pedestrian routes, stricter enforcement of barriers and enhancing supervisory oversight. While such responses cannot undo the tragedy, they do represent essential steps toward preventing a recurrence.

7. Wider industry and business implications

This case highlights broader risks across sectors: waste, logistics, manufacturing, warehousing, construction—any operation where vehicles and pedestrians share space. Regulators will increasingly focus on these interactions, and enforcement action is likely to rise.

For business leaders, this means investment not only in infrastructure but in behaviour-based safety, supervision, monitoring and a culture of continuous improvement. Financially, large fines plus loss of productivity and reputation make such incidents unsustainable.

Also, for health & safety professionals this reinforces the message that ‘paper controls’ are insufficient. Real-world alignment, worker behaviour, and dynamic risk review are non-negotiable.

8. Taking action: what your business should do now

- Conduct a full audit of all vehicle/pedestrian interaction zones in your workplace. Mark routes, check signage, barriers, sight lines, reversing procedures.

- Observe worker behaviour during peak operations: does practice match policy? Are shortcuts being used? If yes, why?

- Review supervision and monitoring arrangements. Are supervisors regularly walking the zones? Are non-compliances recorded and acted upon?

- Establish near-miss reporting focused specifically on vehicle movements and pedestrian crossings. Analyse patterns and update controls accordingly.

- Refresh training for all staff (including visitors and management) on vehicle movement hazards, reversing risks and pedestrian route compliance.

- Regularly review reversing procedures, including one-way systems, reversing alarms, banksman procedures, CCTV review, no-go areas during vehicle manoeuvres.

- Engage leadership with high-risk zones as part of the routine management walk. Leadership visibility builds safety credibility.

- Use a safety-performance metric that covers ‘pedestrian route violations’, ‘vehicle/pedestrian near-misses’, and treat these as leading indicators of risk.

9. What this case teaches us about culture

The fact that workers repeatedly bypassed marked safe routes suggests an underlying cultural issue. Barriers and signage were visible—but treated as optional. That points to a gap between what was written and what was lived.

True health & safety culture demands that controls become the norm, not the exception. Supervisors must both enforce and engage—explain the reasoning, encourage ownership, reward compliance, challenge poor behaviour.

It also demands openness about near-misses and hazards, not hiding them. When workers feel able to report concerns without blame, the business gains an early-warning system.

10. What help is available and how OSHAssociation.org can support

For companies looking to strengthen their transport-and-pedestrian safety systems, bodies such as OSHAssociation.org provide valuable resources, guidance and training. From risk-assessment templates focused on vehicle/pedestrian segregation to behavioural safety programmmes, their tools support effective interventions.

If your business hasn’t yet engaged with such organisations, now is the time. Reversing-vehicle hazards are consistently among the highest-risk categories for workplace fatalities and serious injuries. Utilising external expertise helps validate your own systems and embed best practice.

By aligning your internal controls with recognised external standards and monitoring mechanisms from experts like OSHAssociation.org you enhance not just compliance, but safety performance and culture.

11. Conclusion

The case of “Biffa fined nearly £2.5 m” following the death of Mr Tabiri is a stark reminder: it’s not enough to have safety controls on paper. What matters is whether they work in practice, every day, under live conditions. Businesses must shift from thinking of pedestrian/vehicle segregation as a static checkbox to viewing it as a dynamic, living system of routes, devices, supervision, behaviours and review.

For senior leaders, this means prioritising behavioural safety, real-time monitoring, visible leadership, constant review and alignment with sector-specific guidance. The human cost of failure is tragically real—and the financial cost is no less serious.

As you review your own workplace transport risks, ask: “What do I see happening here that the policy says shouldn’t happen?” If you struggle to answer, it’s time for change. And if you need support in building effective systems, regulators, professional bodies and advisory organisations such as OSHAssociation.org are ready to help you raise the bar.

Above all, remember: every worker has the right to return home safely. Make sure your systems, culture and leadership fully reflect that truth.